Economical, reliable, maintenance-free, energy-efficient pulverizing system available by incorporating the latest developments

vertical roller mill is among essentially the most commonly- made use of vertical roller mill which can be greatly applied in all kinds of preparing of mineral powders and coal powders including the processing of material ores and gypsum mine.

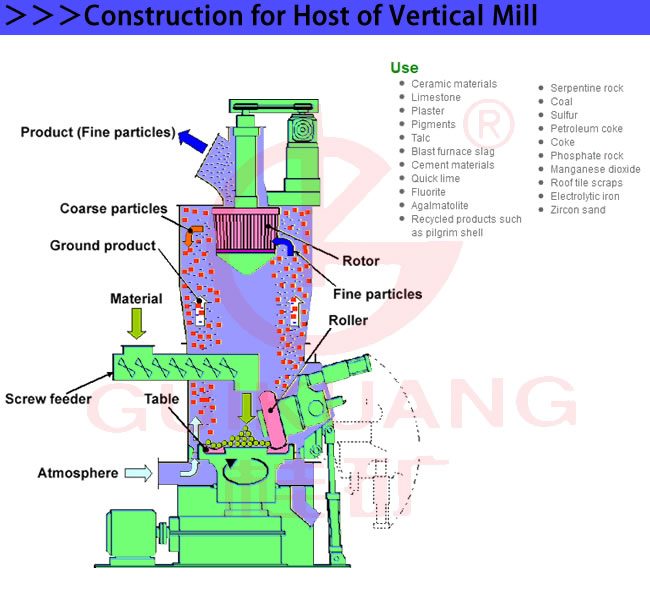

Work principle

The grinding table is drived to rotate by the motor through decelerator,the material is feed to the center of the

grinding table through the inlet by the screw conveyor,at the same time, air comes into the roller mill from the

air inlet.because of the centrifugal force,the material move to the edge of grinding table from the center.The

materials are crushed by the grinding roller when by pass of the groove on the grinding table.The crusher

materials continue to move to the edge of the grinding table unit taken away by the airstream. Then the

bigger materials fall down the grinding table and the process of crushing continues.When the material

in the airstream pass the classifier on the top of the mill,the materials fall down the grinding table from

the taper filter under the force of guide ales afblade.The fine powder comes out with the airstream,and

is gathered by the catcher of the system.The powder gathered is the final product of roller mill.

Accessory equipment |

|

|

Rotary feeder |

Used to feed materials. |

|

Whizzer separator |

Used to classify coarse particles. |

|

Cyclone collector |

Used to collect products. |

|

Main fan |

Used to transport products and circulate air. |

|

Vent fan |

Used to exhaust surplus air. |

|

Bag filter |

Used to support collection of products. |

|

Ducts |

Used to transport products and circulate air. |

Technical Advantage:

1. High automatic level: The equipment using PLC remote control system to unified control, sensitive and reliable.

2.High quality of powder: Grinding wheel and the ring does not directly contact , through the indirect effect ,forces acting on the material. The grinding time of certain material in the main unit is short.Powders crystal structure don't change, good solubility, good dispersity, low iron, unstained.

3. High classification accuracy: Grading system uses horizontal four (or three) turbine classifier. Classification accuracy is high, the average particle size is fine, finished product can be set within 80-1500 mesh.

4. Easy maintenance:By turning the rockeres well as hydraulic system maintenance,the hard surfacing,roller and ring can be maintained within short time,and reduce the loss because of stop operation.

5. Good sealing performance: system work under negative pressure, no dust out , environmental protection.

6. Long service life for wearing parts: because of grinding wheel and ring surface is made of high-quality wear-resisting material ,it’s has long service life.

Company

Company