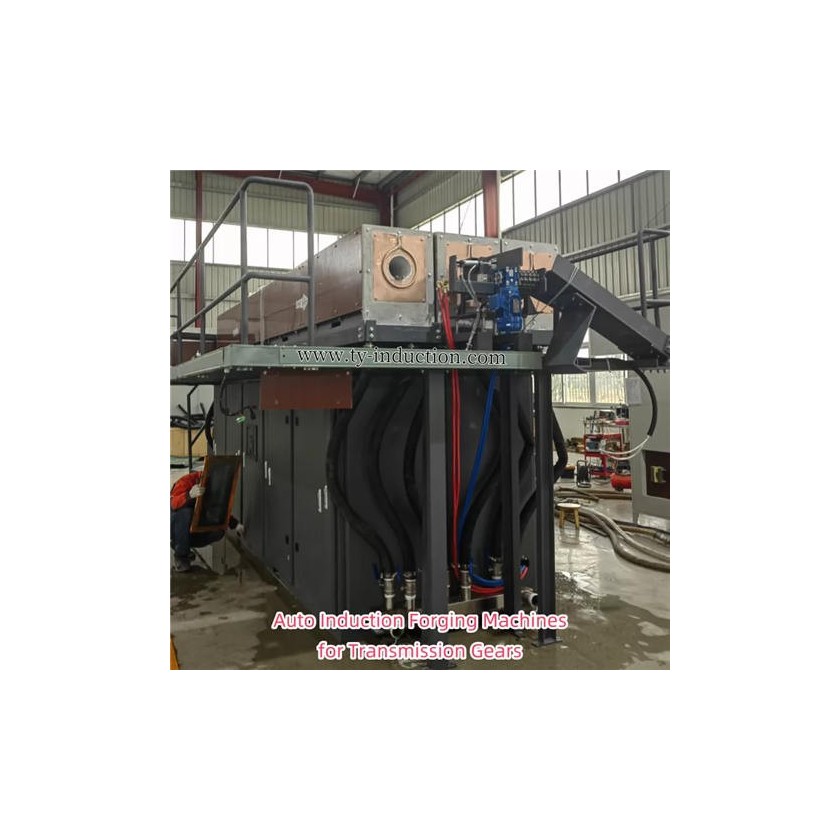

The Advanced Auto Induction Forging system for Transmission Gears is a state-of-the-art solution designed to enhance production efficiency and quality. It features a 1000kw induction power supply based on IGBT technology, ensuring robust and reliable performance.

Minimal Installation and Operating Space

This system boasts an integrated design that combines the induction power supply with inductors of three different sizes. This compact configuration minimizes the installation and operating space required, making it an ideal choice for facilities with limited floor space.

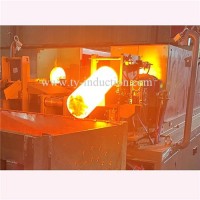

Quick Setup and Changeover

Designed for efficiency, the automatic induction forging equipment allows for quick and automatic switching between three different sizes of inductors. This capability enables rapid setup and changeover, significantly reducing downtime and enhancing the production of transmission gears. This feature is particularly crucial for automotive manufacturers who need to meet tight production deadlines and demand fast turnaround times.

Precise Temperature Control

The system incorporates an infrared thermometer that enables precise temperature control. The controller classifies the workpiece into three categories: qualified, high temperature, and low temperature, based on the detected temperature. A cylinder then sorts the workpiece into different channels, ensuring that every processed workpiece meets the quality standards. This level of control prevents overheating and ensures that the gears are forged with optimal metallurgical properties.

Customized Heating Profiles

The auto induction forging machine can be programmed to follow customized heating profiles, tailored to the specific requirements of the transmission gears being forged. This flexibility allows for the production of gears with varying shapes, sizes, and materials, all while maintaining a high level of precision and quality.

Energy Efficiency

Designed with sustainability in mind, the auto induction forging furnace is highly energy-efficient. By utilizing electromagnetic induction for heating, it consumes less energy compared to traditional heating methods. This not only helps manufacturers reduce their carbon footprint but also lowers their operating costs, making it an environmentally friendly and cost-effective option for forging transmission gears.