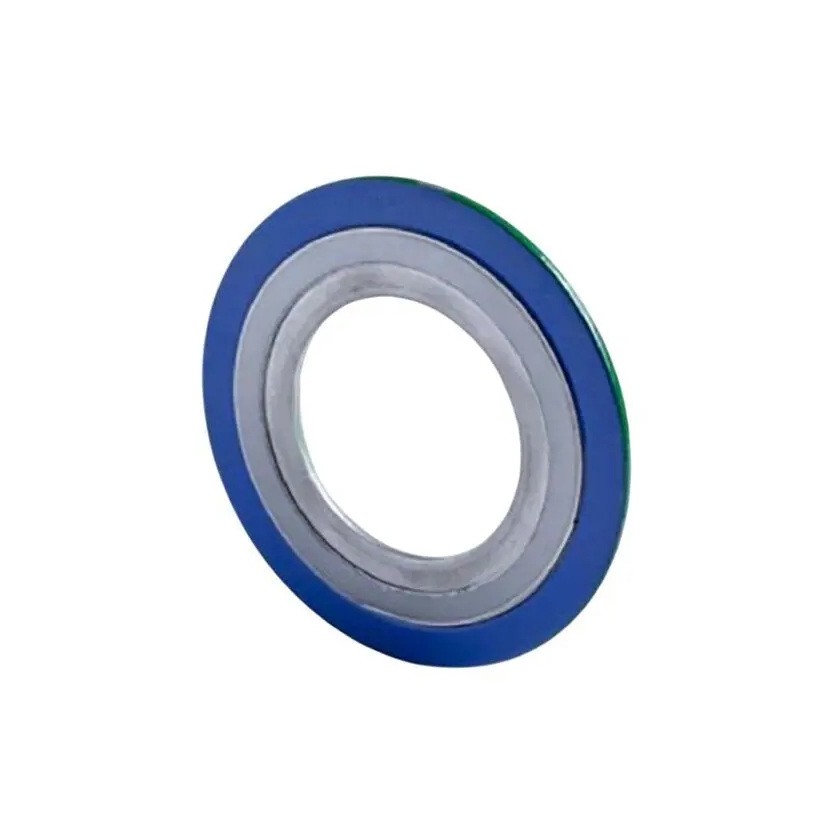

Our Spiral Wound Gasket Plant in China specializes in the production of high-quality spiral wound gaskets engineered for reliable sealing in demanding industrial environments. Each gasket is manufactured with precision-fitted metal inner and outer rings, combined with a spirally wound metal strip and flexible graphite filler to deliver outstanding mechanical strength and sealing integrity.

The inner ring enhances compression control and protects the gasket from process media, while the outer ring ensures accurate centering within the flange assembly and prevents over-compression during installation. The spiral winding structure provides excellent resilience, allowing the gasket to maintain a tight seal under fluctuating pressure and temperature conditions.

Designed for use with flat face (FF) and raised face (RF) flanges, these spiral wound gaskets deliver exceptional sealing performance with proven low-emission characteristics, effectively minimizing leakage and meeting stringent environmental and safety requirements. Their ability to withstand high pressures and elevated temperatures makes them ideal for critical service applications.

Our spiral wound gaskets are widely used across industries such as oil and gas, petrochemical, chemical processing, power generation, and refining, where precision, durability, and operational efficiency are essential. Manufactured under strict quality control, they provide long service life, reduced maintenance needs, and dependable performance in the most demanding sealing applications.