Pad Printing Silicone Rubber Application:

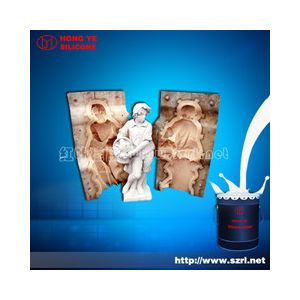

Pad printing silicone rubber is mainly applicable to the printing of irregular patterns on plastic toys, electroplating products, electronic toys, trademarks, artwork gifts, stationery, etc.

Pad Printing Silicone Rubber Features and Advantages:

|

Viscosity

(cps)

|

Hardness

(Ao)

|

Tensile Strength (Kgf/cm2)

|

Tear Strength (kgf/cm)

|

Elongation

(%)

|

Mixing ratio (%)

|

Pot Life (H)

|

Curing Time(H)

|

|

|

901

|

32000

|

21

|

32

|

17

|

390

|

2-3

|

0.5

|

2-4

|

|

902

|

28000

|

28

|

35

|

20

|

400

|

2-3

|

0.5

|

2-4

|

|

912

|

28000

|

29

|

40

|

21

|

380

|

2-3

|

0.5

|

2-4

|

|

916

|

39000

|

14

|

34

|

24

|

480

|

2-3

|

0.5

|

2-4

|

|

918

|

20000

|

26

|

38

|

19

|

380

|

2-3

|

0.5

|

2-4

|

901#/902#/912#/916#/918# pad printing silicone rubber has the advantage of good printing effects, fine quality, good resilience and without any impurity. The silicone pad is a carrier which transfers the patterns from the steel plate onto the surface of products.

Pad Printing Silicone Rubber Operations:

Firstly, clean the mold with detergent, and dry it by a piece of cloth or an air gun, then spray the mold with a layer of release agent;

Secondly, the addition of silicone oil. The ratio of pad printing silicon rubber to the silicon oil depends on the size of pattern which customer needs to print. The larger the pattern is, the softer the printing pad should be, and more silicon oil needs to add. Contrarily, if a silicon pad with high hardness needed, silicon oil should be added less or none. General hardness of the printing pad is 15A°~-25 A°. If too much silicon oil added in the silicon rubber, the printing pad will be too soft, and this will limit the printing times. Because silicon oil will destroy the molecular of the silicon rubber, no matter how supreme quality the silicon rubber is. And therefore, the printing pad will be abrasive and intolerant. General mixing proportion is 30-50g silicone oil to 100g liquid silicone rubber.

Thirdly, the addition of curing agent. Mix 100g silicon and 30-50g silicon oil sufficiently and evenly, then add the curing agent which is 2%-3% of the total weight of the silicon and the silicon oil, keep stirring for 2-3 minutes, and then deair to remove the air bubbles.

Any questions of pad printing silicon rubber,please feel free to contactMs. Kaka.

Phone Num.: 0086-0755-89212380

Mob: 0086-18938867544

Fax: 0086-0755-89948030

Skype: kakaye28

E-mail: hysa (at) szrl (dot) net

Website: www (dot) szrl (dot) net

Company

Company