1. Maximum bed rotation diameter up to 700mm

2. Maximum processing length up to 400mm

Features

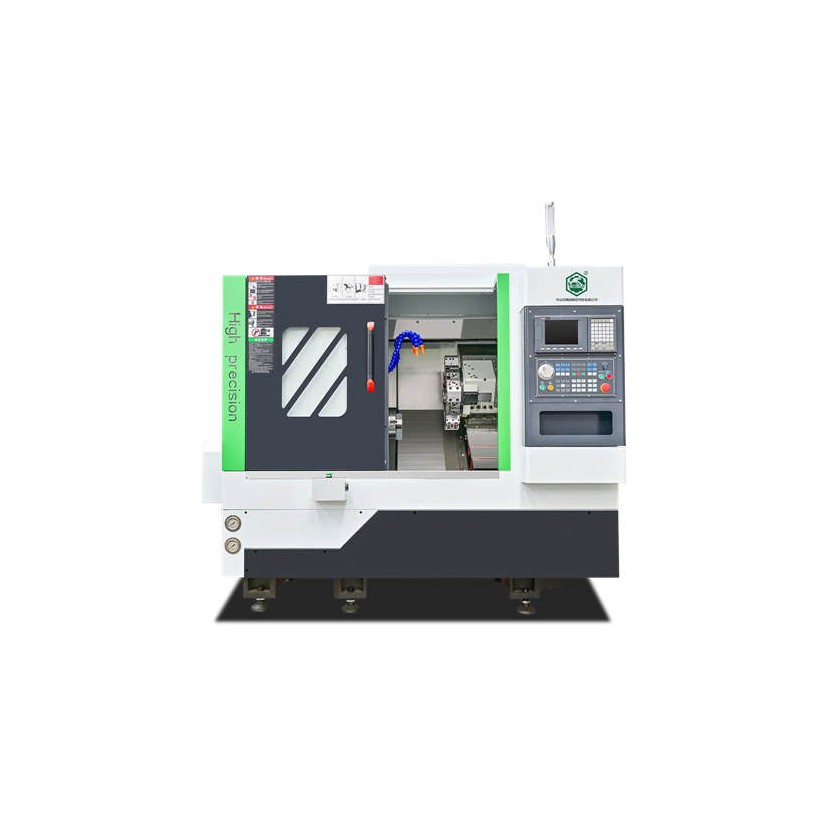

a. CNC lathe machine features an integrated design with a robust casting base and a 35° inclined bed, enhancing overall rigidity. Optimized through finite element analysis, the cast iron reinforcement ribs ensure material efficiency.

b. The X/Z axis feed adopts a servo motor directly connected to the lead screw through a large torque and low inertia elastic coupling to ensure positioning accuracy and repeatability.

c. Equipped with a Taiwan HIWN/PMI high-precision C3 screw guide, this CNC lathe offers dual encoder for the main motor and spindle, and CNC lathe machine utilizing M3 communication for enhanced precision and performance.

This CNC lathe with servo turret - CK46S enables precision turning of copper alloys (brass/bronze), aluminum alloys, ferrous metals (carbon/stainless steel), and engineering plastics, handling bar stocks (Φ≤45mm) and individual workpieces (disc type, Φ≤500mm). Ideal for manufacturing valve components, transmission parts, and hydraulic fittings etc. , requiring multi-material compatibility and 0.003mm accuracy.

A Gang Type CNC Lathe is a specialized computer-controlled turning machine designed for high-speed and precise machining of small to medium-sized workpieces. Unlike traditional lathes, it features a gang tool post with multiple cutting tools mounted on a single slide, allowing simultaneous or sequential machining operations without tool change delays.